Guide to Engaging China Injection Molding Suppliers

The important meeting has recently finished, your new product has been approved, time is pressing, and the budget is… well, let’s just say it’s tight.. And suddenly someone—perhaps your superior or the finance head—says the fateful words that make any project manager’s heart skip a beat: “We should look at sourcing this from China.”

You nod, of course. On paper, it’s logical. Savings can be substantial. However, your brain is racing with concerns. You’ve heard all the horror stories, right? The quality disasters, the communication black holes, the shipment that shows up three months late looking nothing like the sample. It’s like balancing on a tightrope between a massive cost advantage and project disaster.

However, here’s the reality. Procuring plastic mold needn’t be a roll of the dice. It’s simply another project with clear steps. And like any project, it succeeds or fails based on the process you follow. It isn’t about the cheapest offer but about choosing the right supplier and running the process transparently. Disregard those scary tales. Here’s a practical playbook to nail it.

Initial Step: Prepare Your Information

Before you even whisper the word “supplier” or open a browser tab to Alibaba, you need to get your own house in order. Honestly, more than half of all overseas manufacturing problems start right here, with a weak or incomplete information package. Don’t assume a remote factory can guess your needs. Sending a vague request is like asking a builder to quote you for “a house.” The responses you get will be all over the map, and none of them will be useful.

Your goal is to create a Request for Quotation, or RFQ, package that is so clear, so detailed, that it’s nearly impossible to misinterpret. It’s the cornerstone of your entire effort.

So, what goes in it?

Start with your 3D design files. These are non-negotiable. Use standard formats such as STEP or IGS to ensure compatibility. This is the authoritative CAD geometry.

However, 3D alone won’t cut it. Add comprehensive 2D plans. This details critical info missing from the 3D file. I’m talking about critical tolerances (like ‘25.00±0.05 mm’), material specifications, required surface finishes, and notes on which features are absolutely critical to function. If a specific surface needs to be perfectly smooth for a seal, or a particular hole diameter is vital for an assembly, your 2D drawing needs to shout it from the rooftops.

Then specify the material. Don’t just say “Plastic.” Don’t even just say “ABS.” Be explicit. Specify SABIC Cycolac MG38 in black, if that’s the resin you need. Why so detailed? Because plastic grades vary by the thousands. Defining the exact material guarantees the performance and appearance you designed with what is plastic mold.

Your supplier might propose substitutes, but you must set the baseline.

Finally, include the business details. State your EAU. They need clarity: is it 1,000 total shots or a million units per annum? Cavity count, tooling cost, and per-unit pricing depend on volume.

Hunting for the Best Supplier

Now that your RFQ is pristine. who will you target? The web is vast but overwhelming. Locating vendors is easy; vetting them is the real challenge.

Your search will likely start on platforms like Alibaba or Made-in-China.com. They let you survey dozens of suppliers quickly. But think of them as a starting point, not the finish line. Narrow your pool to about a dozen promising firms.

But don’t stop there. Consider using a sourcing agent. True, they charge a fee. Yet top agents deliver reliable, audited suppliers. They are your person on the ground, navigating the language and cultural barriers. As a newcomer, this offers priceless security. It’s schedule protection.

Also consider trade fairs. With budget permitting, Chinaplas or similar shows are invaluable. Nothing beats a face-to-face conversation. Inspect prototypes, interview engineers, and sense their capabilities. Plus, ask peers for referrals. Tap your professional contacts. A solid referral can be more valuable than any ad.

Sorting the Contenders from the Pretenders

With your RFQ dispatched to dozens of firms, bids begin to arrive. You’ll see ridiculously low offers and steep quotes. Now, sift through and shortlist 2–3 reliable candidates.

What’s the method? It involves both metrics and gut feel.

Begin with responsiveness. Are their replies prompt and clear? Can they handle detailed English exchanges? But the key: do they probe your RFQ? Top vendors will critique and inquire. For instance: “Draft angle here could improve mold release. Tolerance check via CMM adds cost—proceed?” That’s a huge positive sign. It shows they’re engaged and experienced. A “Sure, no issues” vendor often means trouble.

Next, dig into their technical capabilities. Get their tooling inventory. More importantly, ask for case studies of parts they’ve made that are similar to yours in size, complexity, or material. A small-gear shop won’t cut it for a big housing.

Next up: the factory audit. You can’t skip this. You would never hire a critical employee without an interview, so why would you send tens of thousands of dollars for a tool to a company you’ve never truly vetted? Either visit in person or engage a local audit service. They dispatch an on-site auditor for a day. They will verify the company is real, check their quality certifications like ISO 9001, assess the condition of their machinery, and get a general feel for the operation. That small investment can save you thousands.

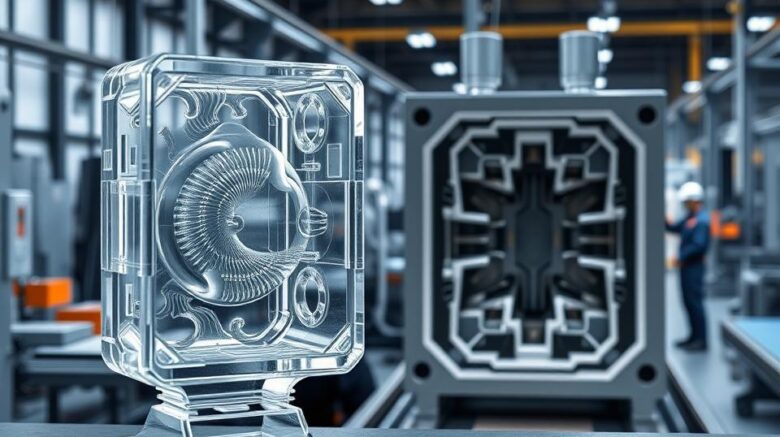

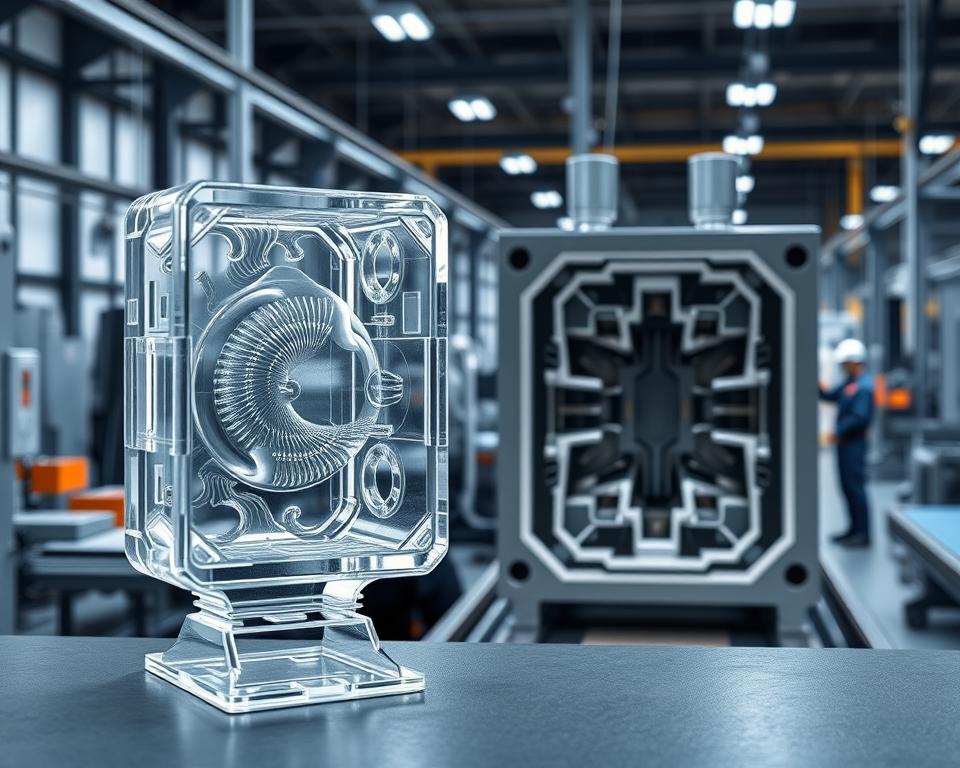

From Digital File to Physical Part

After picking your vendor, you’ve negotiated the price and payment terms—a common structure is 50% of the tooling cost upfront to begin work, and the final 50% after you approve the first samples. Now the process kicks off.

Your supplier’s first deliverable is a DFM analysis. Design for Manufacturability (DFM) is essential. It’s the engineering critique for moldability. The report calls out sink-risk zones, stress-causing corners, and draft angle gaps. A thorough DFM is a sign of a professional operation. It becomes a joint effort. You iterate with their team to optimize the mold.

When you greenlight the DFM, they machine the mold. Weeks on, you receive the thrilling “T1 samples shipped” notification. These are your initial mold shots. It’s your test of success.

Expect T1s to need tweaks. That’s standard process. There will be tiny imperfections, a dimension that’s slightly out of spec, or a blemish on the surface. You supply feedback, they tweak the tool, and T2 plastic mold samples follow. It could require several iterations. The key for you, as the project manager, is to have this iteration loop built into your timeline from the start.

At last, you get the perfect shot. It matches all specs, has a pristine finish, and works as required. This is your golden sample. You ratify it, and it becomes the quality yardstick for production.

Final Steps to Mass Production

Landing the golden sample is huge, yet the project continues. Next up: mass manufacturing. How do you maintain consistency for part 10,000?

Put a strong QC process in place. This often involves a pre-shipment inspection. Again, you can hire a third-party service. They’ll sample parts, check dimensions and finish versus your drawings and golden sample, and report. You receive a full report with images and measurements. Only after you approve this report do you authorize the shipment and send the final payment. This step saves you from a container of rejects.

Don’t forget shipping details. Understand the shipping terms, or Incoterms. Are you on FOB terms, where they load and you take over? Or is it EXW (Ex Works), where you are responsible for picking it up from their factory door? These choices hugely affect landed cost.

China sourcing is a long-haul effort. It’s about building a relationship with your supplier. Treat them like a partner, not just a line item on a spreadsheet. Transparent dialogue, respect, and process discipline win. It’s a challenging project, no doubt. But with this framework, it’s one you can absolutely nail, delivering the cost savings everyone wants without sacrificing your sanity—or the quality of your product. You’ve got this.